- Heavy Duty 20-gauge Powder Painted Cold Rolled Steel.

- Conveniently Located Lighted Switch.

- Choose Between Rocker or Dimmer Switch for Custom Brightness Adjustment.

- Our Most Advanced Lighting.

- 3-foot Cord Plugs Into the Top of the Upright.

- Color: 5,000 Kelvin. Similar to Fluorescent Daylight.

- Color: 3,500 Kelvin. Balanced Neutral White, Softer Than Daylight.

The cord that plugs into the top of our (exclusive) uprights with an outlet at the top.

! Uprights & Light Frame Required.

! Upright Mounted Plug Included when you Purchase.

! Inventoried in white. Add $10 each for special color.

* Standard 3 Foot Cord, Optional 8 Foot Cord.

- Standard: ESD laminate top with grounded frame under standard (insulating) powder coat.

- Upgrade: Entire frame, legs, and structure coated with static-dissipative ESD paint (10⁶–<10⁹ Ω to ground).

- Spec: Fits the ANSI/ESD S4.1 worksurface guideline of ≥1×10⁶ to <1×10⁹ Ω and the ANSI/ESD S20.20 requirement of <1×10⁹ Ω to ground.

- Result: Top, frame, and legs all function as one ESD-controlled workstation, not just the worksurface.

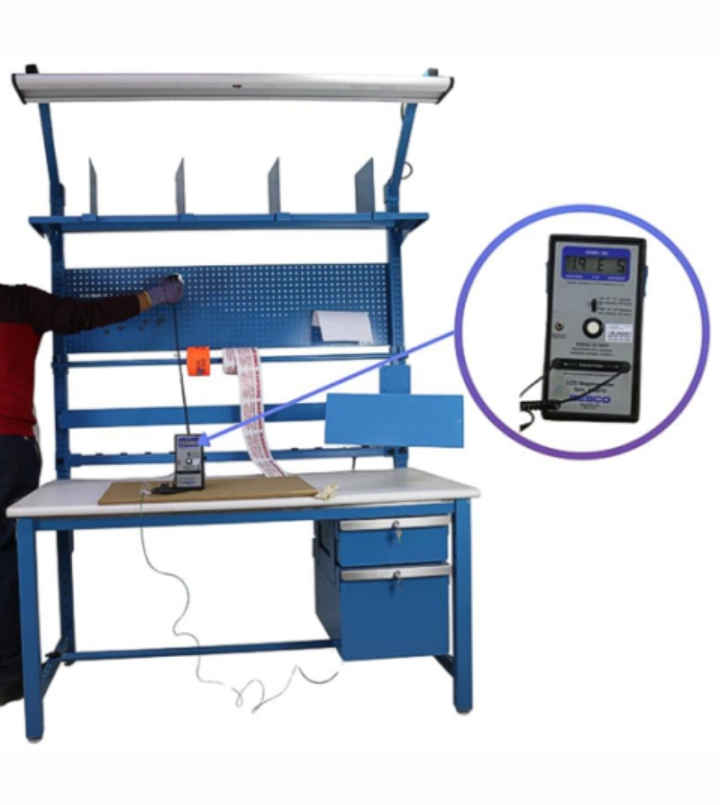

Electrostatic Discharge (ESD) Control Testing

Electrostatic discharge (ESD) control testing was performed in accordance with ANSI/ESD S20.20-2021, using the ANSI/ESD STM4.1-2017 test method for worksurfaces.

The objective of this testing is to verify that the ESD paint and steel structure meet the required Resistance to Ground (RtG) limits so the bench is suitable for use in an Electrostatic Protected Area (EPA).

Product Under Test:

ESD workbench with ESD-finished steel structure.

Scope and Approach

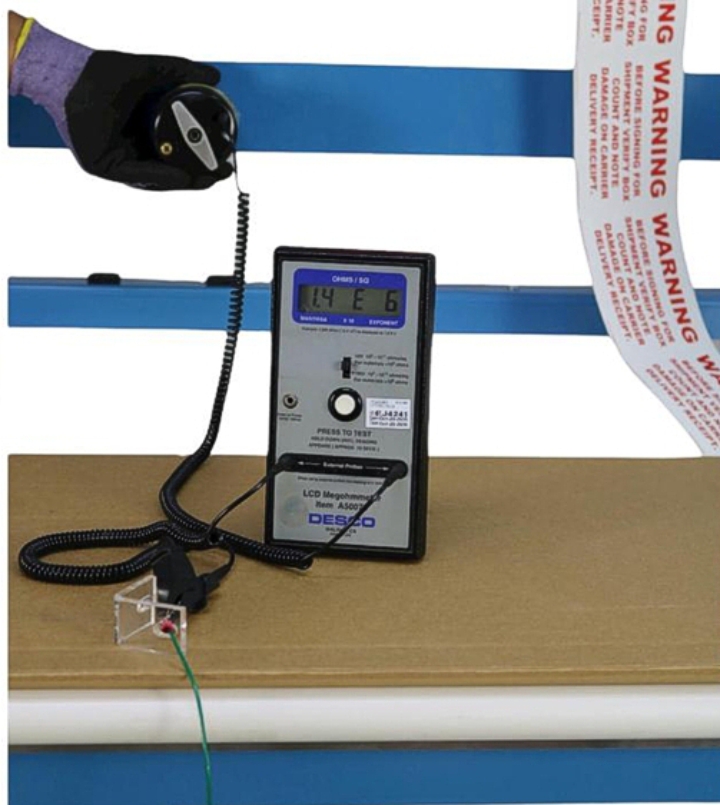

Testing was carried out on the ESD workbench at representative contact points along the painted structure, following the discharge path from the ESD paint through the frame to the grounding connection point. This validates that the bench provides a controlled, compliant path to ground across the structure for use in EPA environments.Tools Used

To perform the resistance measurements, we used a DESCO LCD Megohmmeter (Item A50070), a meter designed for testing ESD worksurfaces and grounding paths.

Measurements were taken by connecting one terminal of the meter to the ground reference point and placing the test electrode on each selected point of the painted structure.

Note: According to ANSI/ESD S20.20-2021, the maximum allowable Resistance to Ground (RtG) for ESD worksurfaces in an EPA is < 1.0 × 10⁹ ohms.

PROCESS & RESULTS: Work Surfaces

Measurements were taken from the main worksurface and shelving to the ground point. Both surfaces showed excellent conductivity.

| Test Location | Result (Ohms) | Limit | Status |

|---|---|---|---|

| Worksurface Top | 4.4 × 10⁸ | < 1×10⁹ | PASS |

| Top Shelf | 3.3 × 10⁶ | < 1×10⁹ | PASS |

PROCESS & RESULTS: Accessories

Vertical accessories and holders were tested to ensure the paint provides a path to ground throughout the structure.

| Test Location | Result (Ohms) | Limit | Status |

|---|---|---|---|

| Pegboard | 1.9 × 10⁵ | < 1×10⁹ | PASS |

| Roll Holder | 2.0 × 10⁷ | < 1×10⁹ | PASS |

| Bin Box Rail | 1.4 × 10⁶ | < 1×10⁹ | PASS |

| MHLK (LCD Monitor + Keyboard Holder) | 3.7 × 10⁷ | < 1×10⁹ | PASS |

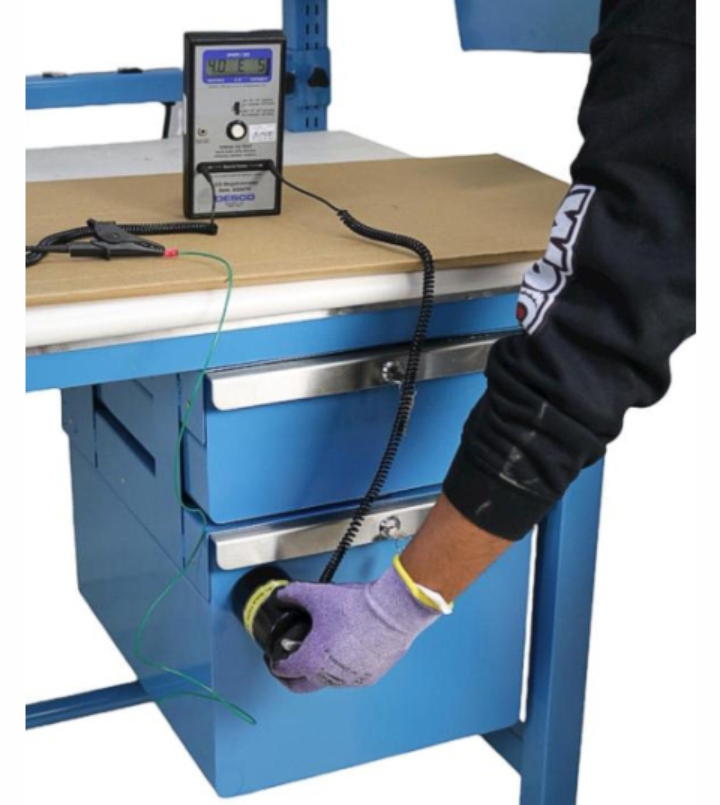

PROCESS & RESULTS: Storage & Ground

Drawers and the main frame were tested. All components passed, ensuring a safe discharge path for the operator and equipment.

| Test Location | Result (Ohms) | Limit | Status |

|---|---|---|---|

| Drawer 1 | 1.2 × 10⁵ | < 1×10⁹ | PASS |

| Drawer 2 | 4.0 × 10⁵ | < 1×10⁹ | PASS |

| Frame | 2.1 × 10⁷ | < 1×10⁹ | PASS |

| Power Strip | 2.6 × 10⁷ | < 1×10⁹ | PASS |

Conclusion

Testing demonstrates that the ESD workbench is in full compliance with the Resistance to Ground (RtG) requirements for structures and surfaces that come into contact with static-sensitive items.

- Final Declaration:The product meets the ANSI/ESD S20.20-2021 acceptance limit of < 1.0 × 10⁹ ohms RtG.

- Suitability: The ESD paint and finished steel structure are suitable for use in Electrostatic Protected Areas (EPAs) and provide a compliant foundation for an effective ESD control program.

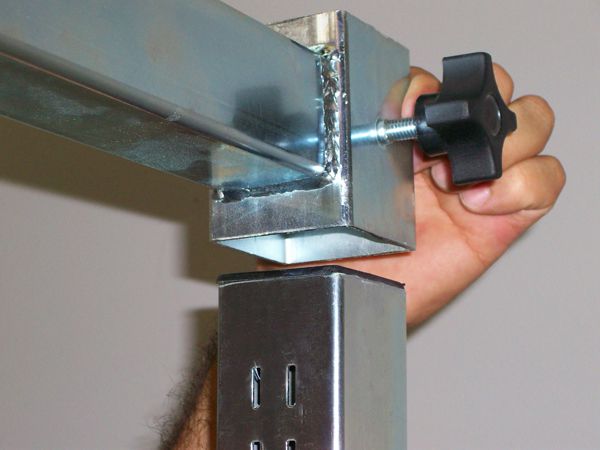

Overhead Light Assembly

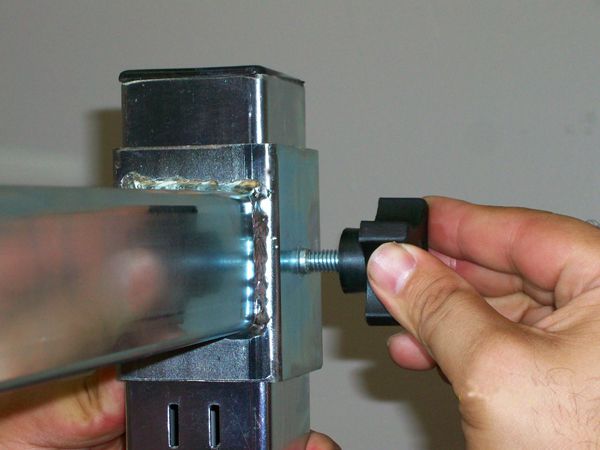

1. This is a job for two people. Unpack the light frame. Form it into a "C" shape and suspend it over the top of the uprights. You can form it with the knobs on the inside or the outside. Make sure the knobs are backed out far enough to allow it to slip over the top. Slide it into desired position.

2. Use the knobs to tighten it down. It does not have to be super tight.

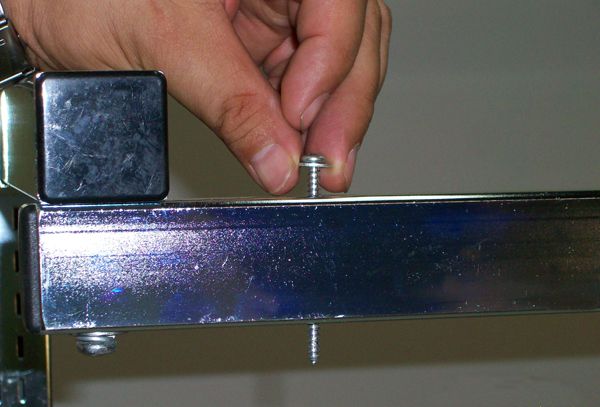

3. Now drop two sheet metal screws with washers into the holes in the top of the long bar.

4. Turn the light facing down, and locate two nylon fasteners.

5. Position the light under the bar with the two screws positioned to go into the nylon fasteners. Insert the screws and tighten them until the light is secure against the bottom of the light frame bracket hinges.