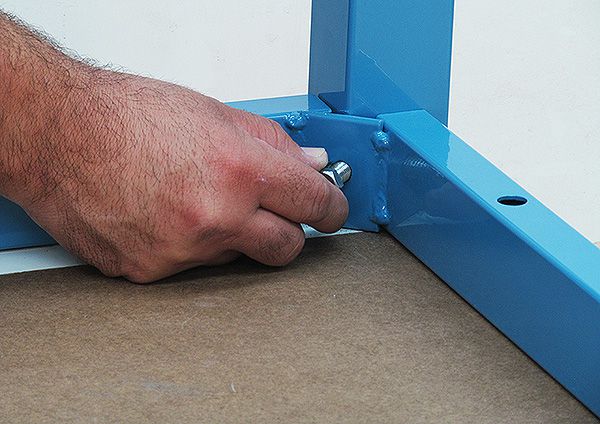

- One Bolt Per Leg Assembly (Factory Assembly Available).

- 6,600# Capacity.

- Pass ANSI, BIFMA, DIN ESD Association Standards.

(American National Standards Institute, Business Industrial Furniture Manufacturers Association, Deutsche Institute Fur Normang). - 1.2" Thick Top.

- Strong 16-gauge Cold Rolled Steel.

- Available 24”, 30”, 36”, 48” Wide or Custom.

- The Legs are Ready for Use with the Footrest Type II. (5 Adjustment levels).

! Although our laminated tops and shelves are very water resistant, they are not recommended for use where running water is present or where constant water spills are possible. These type of wet applications require either stainless steel or resin top tables.

This LisStat™ laminate is formed around the front edge of the work surface and 3" under the front edge.

The ESD LisStat™ laminate is bonder over the aluminum, making the entire top and bottom dissipative from every point.

The tubular steel frame is factory attached to the top by a series of screws.

What is included with an ESD system?

Special Top Features:

1. We Use LisStat™ ESD Laminate: Uses a design which controls the static dissipation rate to meet all ANSI/BIFMA and Federal GSA standards. This laminate carry the static charge across a layer of carbon which is buried just below the surface color layer.

Some of our competitors still use brands of ESD laminate which are made conductive by dipping conventional laminate sheets into a chemical bath, then dry the sheet.

These sheets come from the laminate dipper with a label which, to paraphrase it, reads Do not clean with any products containing water, ammonia, chlorine, or soap. We have replaced hundreds of competitors tops which have lost their ESD properties over time, even though they followed all the manufacturer instructions.

2. We use ESD laminate on the top and all four edges. As surprising as it sounds most other companies either use a non-dissipative rubber strip or use nonconductive laminate on the edges. If you already have a competitors ESD bench, you can spot this by checking to see if the laminate looks identical in color, thickness and texture. If it looks different, check the surface resistivity. It won't be the same.

3. Aluminum underside: We are the only bench manufacturer to use an aluminum sheet to seal the underside of our tops and to assure conductivity. While other makers either leave the core particleboard uncovered on the bottom, paint the bottom or apply a brown paper sheet, we use the only material which completely seals out moisture, and which is 100% conductive. This is important too, as this moisture is the only reason tops warp, and leaving a nonconductive bottom sheet can cause problems in sensitive work areas.

4. Multiple grounding systems: While other brands of benches tout a very special bolt used to ground the surface of the laminate to their grounding system wires, we have eliminated this bolt (And the wires). Because all BenchPro™ bench tops are designed with a full 180 degree laminate radius on the front edge, and because the front laminate wraps under the top of the frame, we simply placed the frame where the fastening screws go through the laminate. This directs the static charge directly into the frame, which is in turn grounded by two conductors we provide for earth grounding purposes. All ESD shelves have the same grounding system.

The two front legs have banana jacks on their front edges to accept wrist strap connectors. The back of the frame has two mounting lugs to attach the two grounding wires which are included with the system. You will find this double system in evidence on every ESD bench and accessory we make.

BenchPro™ ESD work benches are not connected electrically to the floor. We use insulated floor glides so static charges will pass only through the grounding system provided, and so inadvertent charges on the floor can not pass up to the work surface and operator.

The unique characteristics of LisStat™ Static Dissipative Laminate make it ideally suited for a variety of sensitive electronic production applications.

LisStat™ Static Dissipative Laminate Sheets are designed for permanent lamination to work station surfaces.

LisStat™ meets and surpasses all standards for electrical dissipation as they apply to static control, even at low humidity levels. These standards include ANSI/BIFMA, ESDI, GSA and many others.

LisStat™ Static Dissipative Laminate Sheets are designed for permanent lamination to work station surfaces.

All BenchPro™ ESD benches are only available with ergonomic contoured front edges. This way, the ESD laminate conducts the static charges all the way to the steel frame. The steel frame has two wrist strap jacks mounted on the top of the two front legs for convenience. BenchPro™ also provides one grounding wire to take the static from the frame to either an adjoining bench or to ground.

To guarantee a static clear work area, all BenchPro™ ESD bench top have their edges laminated with the same static control laminates as used on the top, while the underside of the tops have a laminated solid aluminum sheet.

- Standard: ESD laminate top with grounded frame under standard (insulating) powder coat.

- Upgrade: Entire frame, legs, and structure coated with static-dissipative ESD paint (10⁶–<10⁹ Ω to ground).

- Spec: Fits the ANSI/ESD S4.1 worksurface guideline of ≥1×10⁶ to <1×10⁹ Ω and the ANSI/ESD S20.20 requirement of <1×10⁹ Ω to ground.

- Result: Top, frame, and legs all function as one ESD-controlled workstation, not just the worksurface.

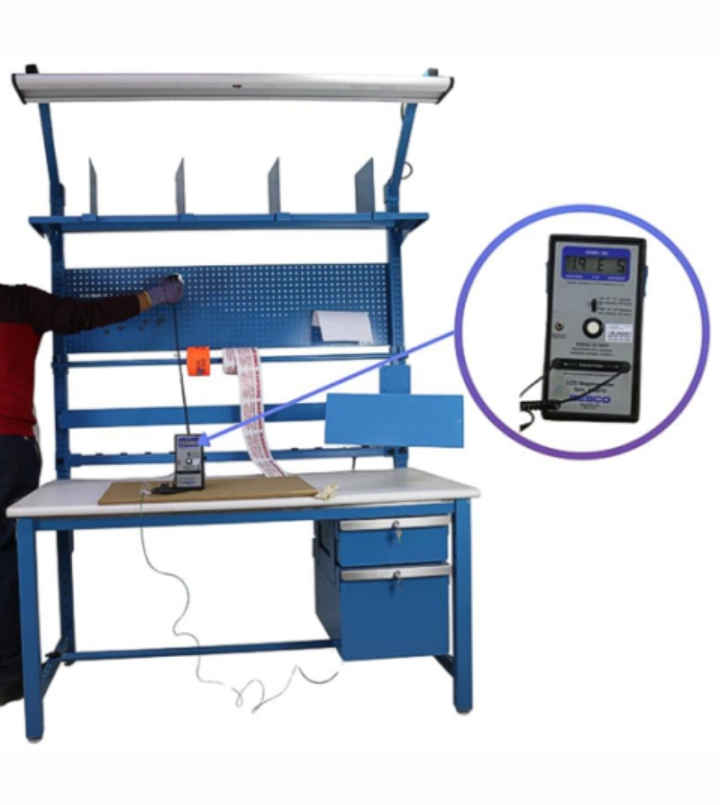

Electrostatic Discharge (ESD) Control Testing

Electrostatic discharge (ESD) control testing was performed in accordance with ANSI/ESD S20.20-2021, using the ANSI/ESD STM4.1-2017 test method for worksurfaces.

The objective of this testing is to verify that the ESD paint and steel structure meet the required Resistance to Ground (RtG) limits so the bench is suitable for use in an Electrostatic Protected Area (EPA).

Product Under Test:

ESD workbench with ESD-finished steel structure.

Scope and Approach

Testing was carried out on the ESD workbench at representative contact points along the painted structure, following the discharge path from the ESD paint through the frame to the grounding connection point. This validates that the bench provides a controlled, compliant path to ground across the structure for use in EPA environments.Tools Used

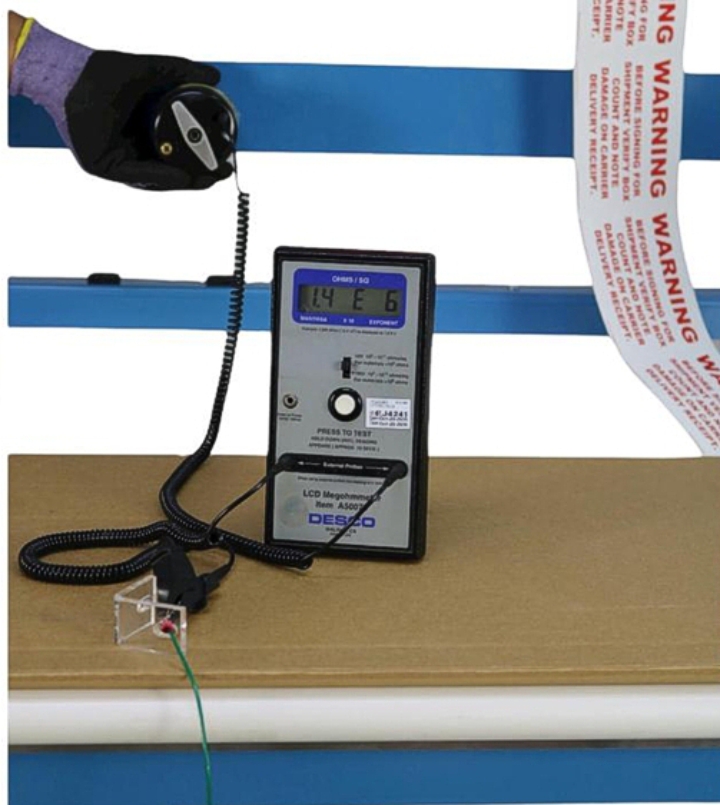

To perform the resistance measurements, we used a DESCO LCD Megohmmeter (Item A50070), a meter designed for testing ESD worksurfaces and grounding paths.

Measurements were taken by connecting one terminal of the meter to the ground reference point and placing the test electrode on each selected point of the painted structure.

Note: According to ANSI/ESD S20.20-2021, the maximum allowable Resistance to Ground (RtG) for ESD worksurfaces in an EPA is < 1.0 × 10⁹ ohms.

PROCESS & RESULTS: Work Surfaces

Measurements were taken from the main worksurface and shelving to the ground point. Both surfaces showed excellent conductivity.

| Test Location | Result (Ohms) | Limit | Status |

|---|---|---|---|

| Worksurface Top | 4.4 × 10⁸ | < 1×10⁹ | PASS |

| Top Shelf | 3.3 × 10⁶ | < 1×10⁹ | PASS |

PROCESS & RESULTS: Accessories

Vertical accessories and holders were tested to ensure the paint provides a path to ground throughout the structure.

| Test Location | Result (Ohms) | Limit | Status |

|---|---|---|---|

| Pegboard | 1.9 × 10⁵ | < 1×10⁹ | PASS |

| Roll Holder | 2.0 × 10⁷ | < 1×10⁹ | PASS |

| Bin Box Rail | 1.4 × 10⁶ | < 1×10⁹ | PASS |

| MHLK (LCD Monitor + Keyboard Holder) | 3.7 × 10⁷ | < 1×10⁹ | PASS |

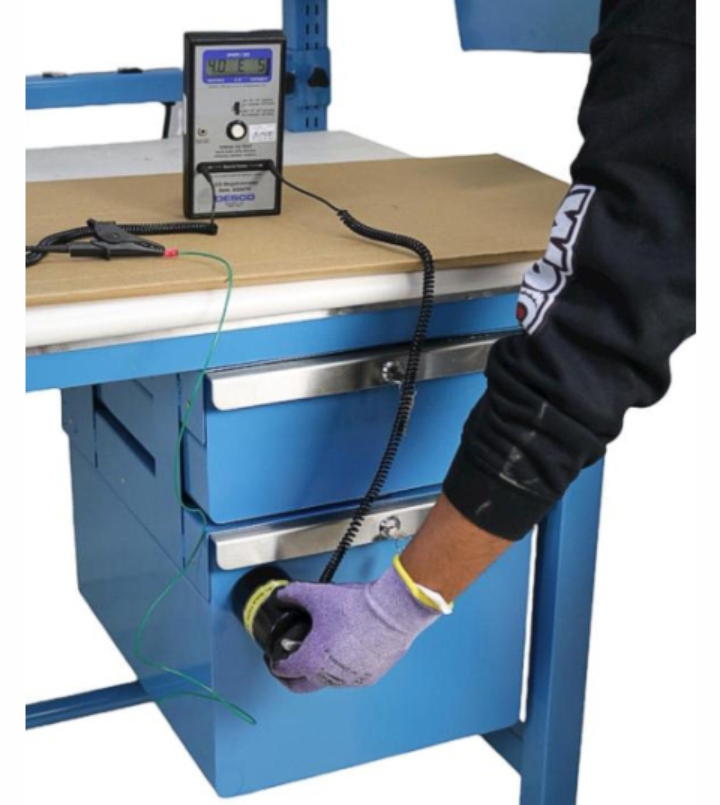

PROCESS & RESULTS: Storage & Ground

Drawers and the main frame were tested. All components passed, ensuring a safe discharge path for the operator and equipment.

| Test Location | Result (Ohms) | Limit | Status |

|---|---|---|---|

| Drawer 1 | 1.2 × 10⁵ | < 1×10⁹ | PASS |

| Drawer 2 | 4.0 × 10⁵ | < 1×10⁹ | PASS |

| Frame | 2.1 × 10⁷ | < 1×10⁹ | PASS |

| Power Strip | 2.6 × 10⁷ | < 1×10⁹ | PASS |

Conclusion

Testing demonstrates that the ESD workbench is in full compliance with the Resistance to Ground (RtG) requirements for structures and surfaces that come into contact with static-sensitive items.

- Final Declaration:The product meets the ANSI/ESD S20.20-2021 acceptance limit of < 1.0 × 10⁹ ohms RtG.

- Suitability: The ESD paint and finished steel structure are suitable for use in Electrostatic Protected Areas (EPAs) and provide a compliant foundation for an effective ESD control program.

Kennedy Series Bench Assembly.

5. If you ordered drawers or CPU holder, assemble them next.

6. Turn it over. You're done!

| Description | Bench Depot | Cisco-Eagle | Proline | Lista |

| Product Image |

|

|

|

|

Price

|

$451.00 | $660.23 | $604.00 | $616.02 |

| Quantity Discount |

2-4 Units = -7%

5-9 Units = -10% 10-24 Units = -12% 25+ Units = -14% |

No Qty Discounts | Not Advertised on Website |

No Qty Discounts |

| Weight Capacity |

6,600 lbs. | 1,000 lbs. | 5,000 lbs. | 1,000 lbs. |

| Lead Time | 1-5 Working Days | 8 to 10 Weeks + Transit Time |

5 working Days | 2-4 Weeks |

| Product Link | Go to Bench Depot | Go To Cisco-Eagle | Go To Proline | Go To Lista |

| Warranty | 25 Years | 5 Years | 1 Year | Lifetime |

| Assembly Instructions |

Click To View 2-3 Minutes 4 Bolts and 28 Welds (4 pcs) |

Click To View 12 Screws and 8 Nuts Needed (20 pcs) |

Click To View

16 Screws, 4 Bolts, 4 Nuts and 10 Washers Needed (34 pcs) |

Click To View 40 Screws and 6 Nuts Needed (46 pcs) |

Workbench WarrantyBenchPro™ has been producing the nation's strongest, longest lasting ergonomic workbenches since 1987. We are so sure our products will perform properly, we offer the following warranty: BenchPro™ benches, options and accessories are warranted to the original purchaser for 25 - years. This includes every component and every function. Exceptions: Workbenches used in multiple shift operations shall have the warranty prorated accordingly. Hydraulic bench lift - system components are warranted for ten - years. All lighting products are warranted for ten - years. For Service: Call BenchPro™ at 888-700-9888 or email info@benchpro.com. Customers only have the obligation to report the problem and BenchPro™ will take care of the rest. BenchPro™ will either refund the entire purchase price including freight (if by our freight carrier) and tax (if any) or replace the product or component that is defective at our discretion. Product Returns:

As we make all orders from base materials, and do not carry an inventory, we charge a "restocking fee" on unneeded and unwanted, yet ordered products. We also charge a restocking fee for products ordered but cancelled after the product is built. This is to cover our repackaging and handling, and remarketing. Customers pay the cost of freight both ways. Restocking fee schedule:

A. Kennedy, Roosevelt Series in standard sizes and colors will be charged 15%.

B. Dewey, Harding, Jefferson, Grant and Adams Series in standard sizes and colors will be charged 30% restocking fee.

C. Any bench in a custom size or color will be charged a 50% restocking fee, as we will have a difficult time reselling them without a large discount.

D. Custom design and non-catalogue items are non-returnable.

E. No product shall be returned after 60 days.

No return of defective product is ever required. (We ask for an electronic photo in cases where we have not seen the problem before).

Freight Damaged Product:

USA freight regulations make freight companies’ drivers responsible for checking shipments for damage when they pick up. Our customers are responsible for checking for damage when receiving and signing for a shipment. We state this on our acknowledgment and invoice in case customers are not aware of the procedure. Once the product is in your facility, we assume you mishandled the product.

Most carriers give us 5 days after delivery to notify them of damage, and will cover the cost of replacements and the freight. If you have a problem, call or write and we will notify the carrier, then replace the product at no charge to you.

From the lawyers: In no case shall BenchPro™, its distributors, employees, related divisions, and other entities be responsible for any direct, consequential or indirect damage caused by the use, inability to use, or incorrect use of our products. Our liability shall be limited to replacement of product or a full refund.

Litigation:

All claims and/or disputes relating to the sale, quality and/or use of our products are to be settled by binding arbitration in the state of California, county of San Diego or any other location mutually agreeable to both parties.

Destruction: Dangerous products should not be put into open waste disposal system until they have been made unserviceable, so no third party can claim them and be injured. (This includes wobbly tables or chairs.)

|

||

| Test | Basis | Description | Pass | Media |

Horizontal Static Load Test. BSI EN 13150:2001 A.3.1 |

Evaluate the ability of the workbench to withstand fatigue stress and wear caused by horizontal forces on the workbench top. | 72.5 Psi is applied ten times at the center of each edge. The feet are securely attached to the floor and a verified distance of inflection is observed. To pass the test, the components of the bench are inspected and verified to have full integrity and no reduction in functionality. |

||

Vertical Static Load Test. BSI EN 13150:2001 A.3.2 |

Evaluate the ability of the workbench to withstand fatigue stresses caused by a vertical impact. |

105 PSI is applied with a downward force 10 times on each edge. Following the test, the bench is inspected for warping or damage. No changes were found. |

||

Sustained Vertical Load Test. BSI EN 13150:2001 A 3.3 |

Evaluate the ability of the workbench to withstand a load for 24 hours. |

1.25 kg / sqm (275 lbs / sqin) is uniformly loaded into the surface of the workbench. 24 hours pass. Eight points are measured to ground before loading, after loading and once the load is removed to determine if there is any inflection of the workbench. The bench is inspected for damage following the test as well. The Kennedy Series is rated to hold up to 5,500 lbs on the surface. This weight had no impact on performance of the bench. |

||

Horizontal Impact Stability Test of Free Standing Workbenches. BSI EN 13150:2001 A 3.5 |

Verify the ability of a workbench to withstand a repeated impact from people walking into it. |

A basketball that is filled to 72.5 psi is attached to a weight and dropped from a standard distance to simulate the impact of a person walking into the table with 110 psi. The impact is repeated and the table is inspected for damage. No damage occurred. |

||

Drop Test of movable workbenches (tables). BSI EN 13150:2001 A 3.7 |

The purpose of this test is to check the strength and functionality of the casters after being tested in free fall strike the floor. |

The workbench is dropped from a height of approximately 6" ten times on each end. The casters are tested in the locked position. Following the test, it was verified that the bench maintained full and smooth motion of the wheels. | ||

Horizontal Fatigue Test. BSI EN 13150:2001 B.3 |

Verify the ability of the workbench to withstand multiple side impacts. | 72.5 PSI are applied 30,000 times to each end while 110 lb. weighs the top of the table down. Following the test, the bench is inspected for damage and none was found. |

||

Vertical Fatigue Test. BSI EN 13150:2001 B.4 |

Evaluate the ability of the workbenches to withstand fatigue stresses and wear caused by vertical forces on the workbench top. | 110 PSI is applied at the middle of the long edge in a downward direction. This is repeated 20,000 times on each edge. Following the test, the bench is inspected for signs of fatigue. No fatigue occurred. | ||

Vertical Impact Test. BSI EN 13150:2001 B.5 |

The purpose of this test is to check the strength and functionality of the workbench. | 55 lb is dropped onto the middle of each edge from 6 in, 8 in and one foot. Following the test, the bench is inspected for structural damage. The bench was not affected. | ||

| BenchPro™ Pull Test | Verfies the ability of the workbench frame to endure a large force from the side. | The bench is secured to the ground and the top is pulled laterally at 450 psi until the bench has shifted 1 inch toward the force. Following this, the bench is inspected for damage and none was found. |

The unique characteristics of LisStat™ Static Dissipative Laminate make it ideally suited for a variety of sensitive electronic production applications.

LisStat™ Static Dissipative Laminate Sheets are designed for permanent lamination to work station surfaces.

LisStat™ meets and surpasses all standards for electrical dissipation as they apply to static control, even at low humidity levels. These standards include ANSI/BIFMA, ESDI, GSA and many others.

LisStat™ Static Dissipative Laminate Sheets are designed for permanent lamination to work station surfaces.

All BenchPro™ ESD benches are only available with ergonomic contoured front edges. This way, the ESD laminate conducts the static charges all the way to the steel frame. The steel frame has two wrist strap jacks mounted on the top of the two front legs for convenience. BenchPro™ also provides one grounding wire to take the static from the frame to either an adjoining bench or to ground.

To guarantee a static clear work area, all BenchPro™ ESD bench top have their edges laminated with the same static control laminates as used on the top, while the underside of the tops have a laminated solid aluminum sheet.

What is the best work surface height for me?

You can order your benches at any work surface height without incurring additional cost, or select the lowest height you believe useful and add either our optional adjustable legs, our electric lift system or our crank-up system.

We have seen orders for almost every work surface height. Some Customers want to sit down and work, others want to stand. Here are some thoughts that may be of assistance:

1. Desks are 30" high.

2. Desk chairs usually have a seat cushion height adjustability range of around 17" to 22".

3. Work surfaces should never be more than 9" higher than the top of the chair range. Conclusion: If you need a work surface higher than 31", you will need a taller chair.

4. Taller chairs usually have a foot ring and a wider base. (Adjustable foot rings are critical as employees come in all sizes too.)

5. Our taller chairs have a seat cushion height adjustability range of 22" to 32". (Some brands have ranges of only 5" or 8".)

6. We do not recommend chairs be used at benches with work surfaces of 37" and higher, as some employees will attempt to "climb" the chair, and could be injured when the chair rolls or tips.